During the summer of 2018, I worked in Manhattan with Open Style Lab to create an accessible leather jacket for Wanda Rosario (a rockstar elderly client with parkinson's disease). I worked with an occupational therapist (Amélie Lavoie) and fashion designer (Nick Paganelli) and contributed my own skills as a maker and engineer to design and create a novel jacket addressing Wanda's needs with the idea of universal adaptability.

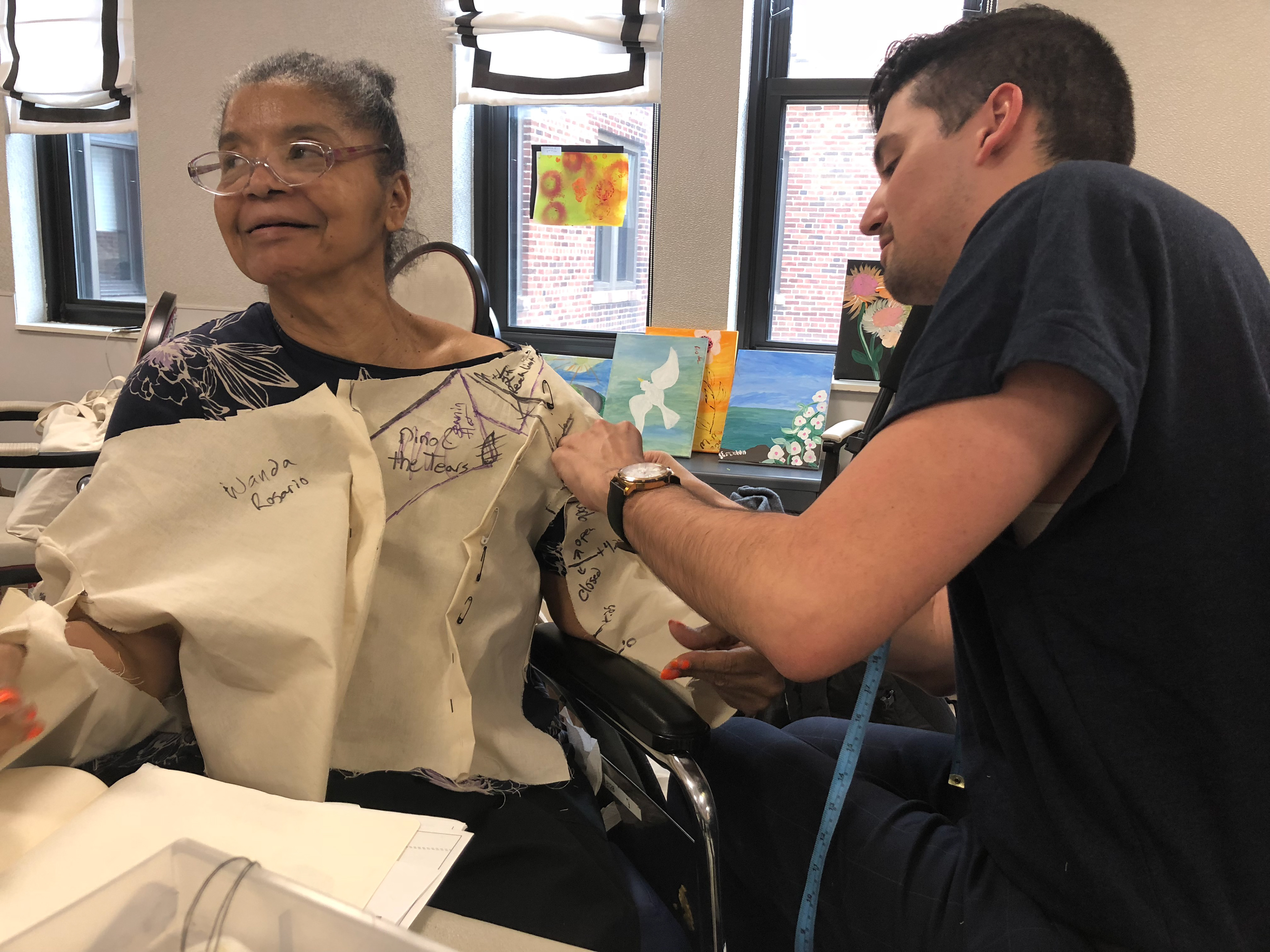

That summer, we interviewed and followed Wanda for 10 weeks to learn her needs. I prototyped several garments to help with her desire to stay warm in the rehab center she lived in, as well as get dressed independently from caretakers - despite her trouble with fine motor movement and reduced strength.

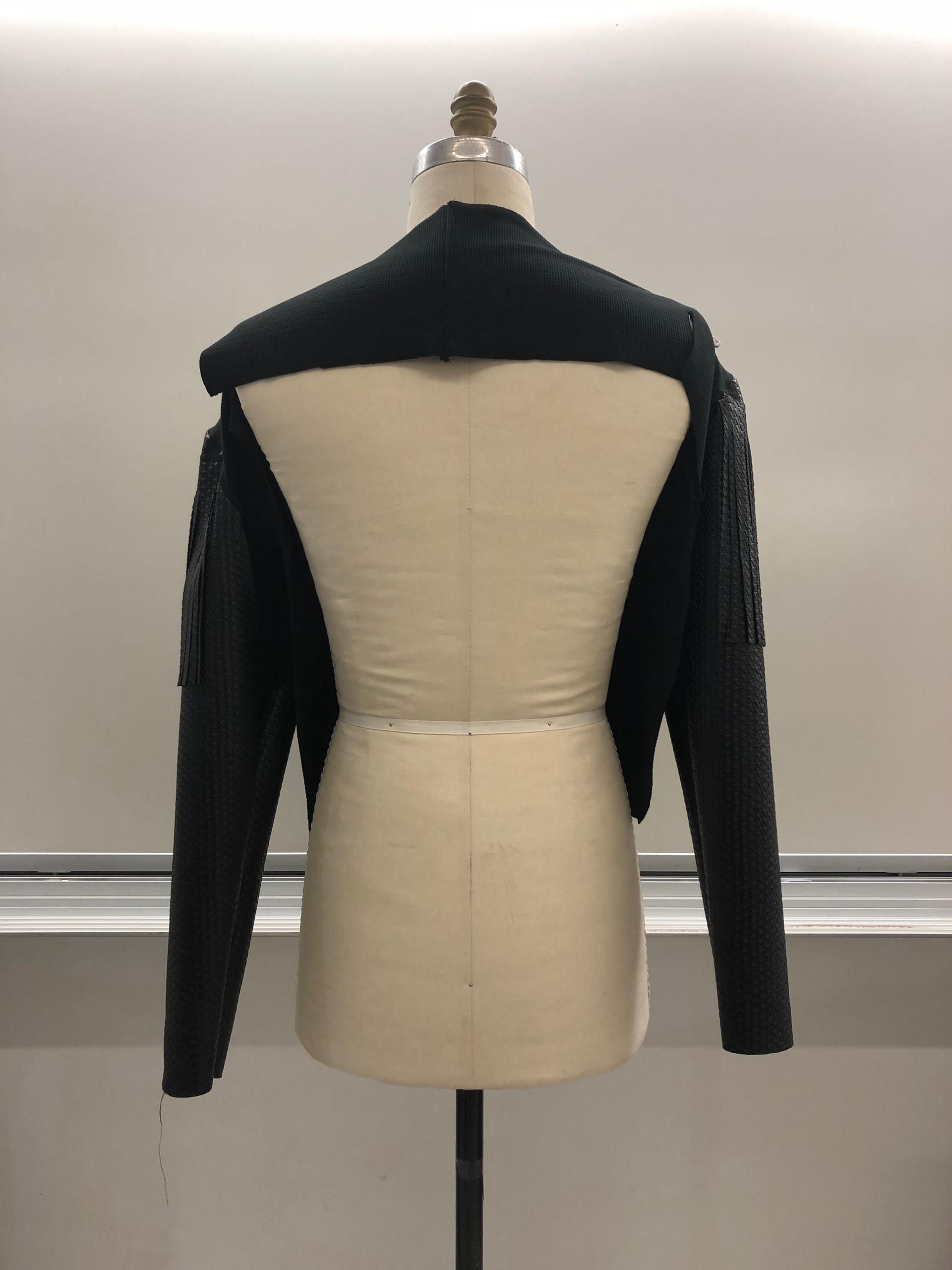

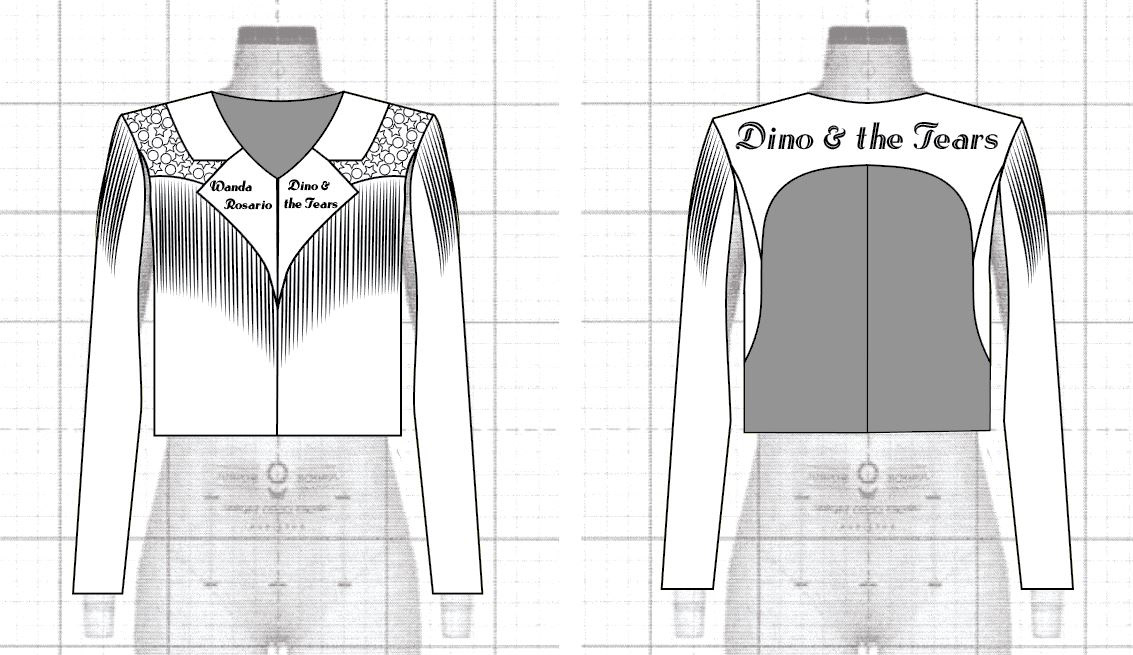

My team eventually created a performance jacket for her (a regular at the rehab's talent show nights) that beckoned back to her days performing at the Apollo. My major contributions to the project were: technical skill during prototyping, exploration of embedded sensors in the fabrics (accelerometers to detect tremors, electrical circuits, etc...), and implemented innovation in laser cutting and 3d-printing on natural fabrics. I used a laser cutter to etch designs on wool, leather and cotton fabrics so we could change outer looks without compromising material performance capabilities (natural fibers >>> synthetics for a number of reasons). I also devised a new way of 3d-printing on natural material fabrics to secure reduced weight accessories on the fabric without fasteners or adhesives.

Below are some pictures of my process, my team, and Wanda rocking our jacket, dubbed the "Cleo."

Throughout the entire summer we closely followed Wanda to learn more about her- her needs, her wants, her capabilities, her environment. We conducted many interviews, and she was more than gracious in teaching us and learning with us about the process of creating accessible clothing.

We spent the first many weeks prototyping. I was helping to design, to sew, to conduct can-do tests with Wanda. We explored many different types of tops, materials and methods. Here are some photos of our process.

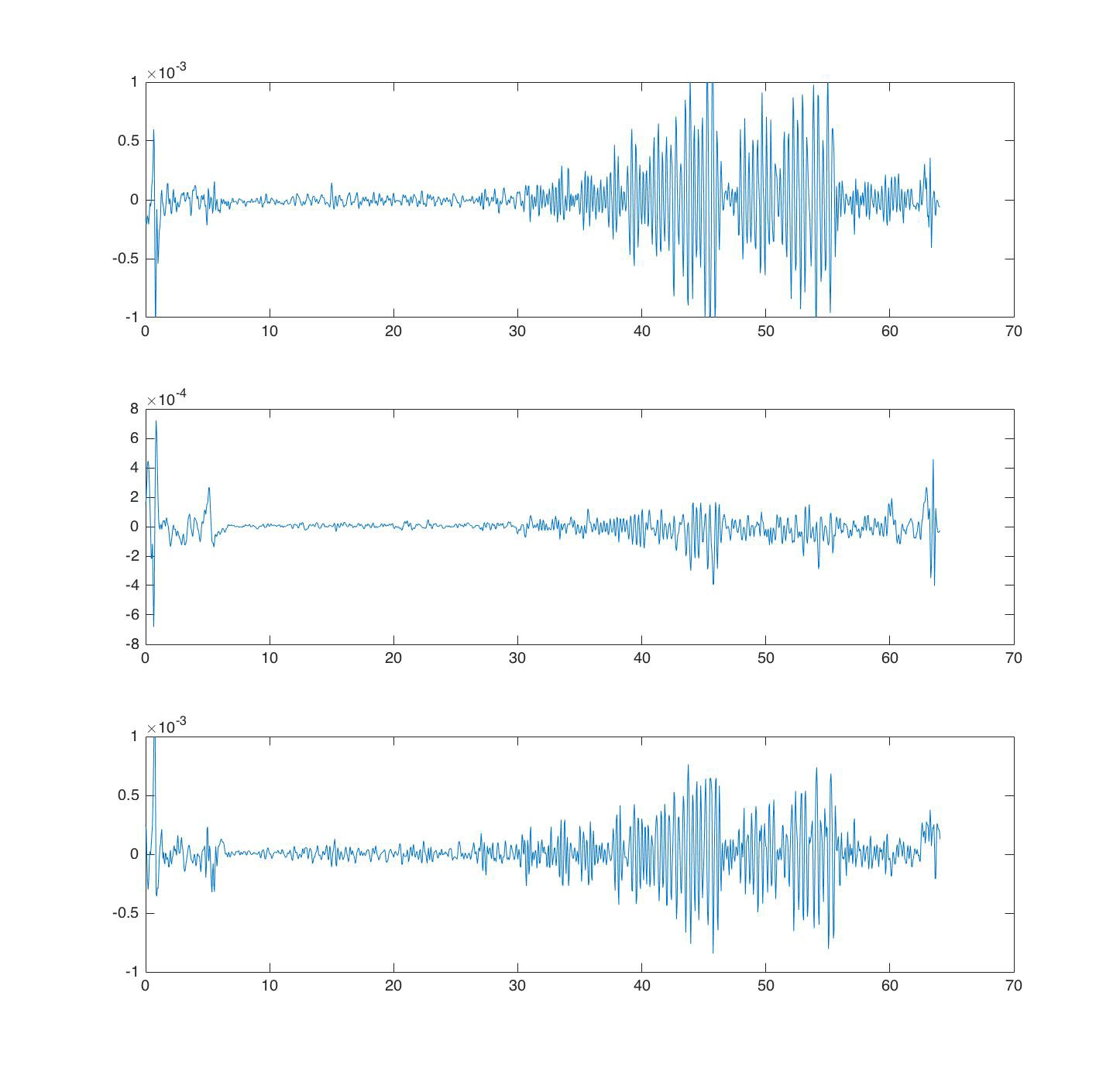

During the prototyping process, I was leading the effort to involve technology innovation in the process. I took measurements of wanda's tremors to see if there was a discernible signal we could pick up on and perhaps create a garment that countered her tremors. I did lots of data processing in matlab that summer and learned about FFT's and the limitations of my phone's accelerometer, haha. I also led the charge of laser cutting prints and on-fabric 3d-printing that summer, and helped other teams with their questions and cuts.

I was also busy that summer learning a new CAD program (CLO 3D! - for clothing and fabric CAD'ing how cool!!!). We made garments in CLO and then used the patterns to create real garments. After editing the fabrics and patterns we would re-upload and edit the CLO files. Ultimately we could render what the jacket would look like on a model and it was pretty spot on to the in-person creation!

Here is the final garment, with details showing the 3d-printed studs I created on the shoulders. The studs weighed ~ 10% the weight of comparable metal+fastener studs and were secured directly to the fabric. This made the jacket as lightweight as possible without compromising on some rock-n-roll style. Wanda loved the attention to detail in that feature and designed and picked out her own stud pattern.

We had a fashion show at the end of the summer with all of the teams. It was my first fashion showing in NYC, and hopefully not my last. I know the next picture is also the first one I showed, but it's so special to me. I had an amazing time that summer and created something both beautiful and technically challenging for a strong and inspiring woman my entire team grew to respect and admire.